Aluminium mobile towers have become an essential tool in construction and maintenance projects due to their versatility, lightweight nature, and ease of assembly. To ensure the safety and longevity of these towers, proper maintenance is crucial. This article provides valuable tips on how to maintain and extend the lifespan of aluminium mobile towers, ensuring their optimal performance and durability throughout their useful life.

Regular Cleaning

Regular cleaning is essential to prevent the build-up of dirt, debris, and corrosive substances on aluminium mobile towers. Use a soft brush or cloth to remove loose particles, and wash the tower with mild soap and water. Avoid using abrasive cleaners or harsh chemicals that can damage the aluminium surface.

Inspect for Damage

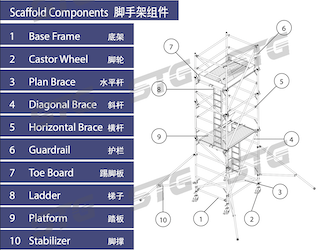

Perform routine inspections to identify any signs of damage or wear on the tower components. Check for cracks, bent frames, loose connections, or missing parts. Address any issues promptly by repairing or replacing damaged components to maintain the tower’s structural integrity.

Lubrication

Applying lubricant to moving parts such as hinges, locks, and wheels helps to reduce friction and prevent premature wear. Use a silicone-based lubricant or a lubricating spray specifically designed for aluminium structures. Regular lubrication will ensure smooth operation and prevent rust or corrosion.

Store Properly

When not in use, store aluminium mobile towers in a clean and dry area away from moisture, extreme temperatures, and corrosive substances. Disassemble the tower if possible, and store it in a secure location to prevent accidental damage. Follow the manufacturer’s guidelines for proper storage procedures.

Conduct Load Capacity Checks

Aluminium mobile towers have specific load capacity limits that should not be exceeded. Regularly check the tower’s load capacity and ensure that it is not overloaded with equipment or materials. Excessive weight can compromise the tower’s stability and increase the risk of accidents.

Maintain Stability

Ensure that the tower’s stabilisers, outriggers, or base plates are properly adjusted and secure before using the tower. Stabilisers help distribute the weight evenly and provide stability on uneven surfaces. Regularly inspect and tighten any loose bolts or fasteners to maintain the tower’s stability and prevent accidents.

Training and User Guidelines

Properly train all individuals who will be using the aluminium mobile tower. Provide clear user guidelines, safety instructions, and best practices to ensure safe assembly, operation, and dismantling of the tower. Emphasise the importance of following manufacturer recommendations and industry safety standards.

Conclusion

By following these maintenance tips, you can significantly extend the lifespan of your aluminium mobile towers while ensuring a safe and productive work environment. Regular cleaning, inspections, lubrication, and adherence to load capacity limits are essential practices that contribute to the tower’s longevity and performance. By prioritising maintenance, you can maximise the value of your investment and ensure the safety of workers utilising these versatile structures in construction and maintenance projects.